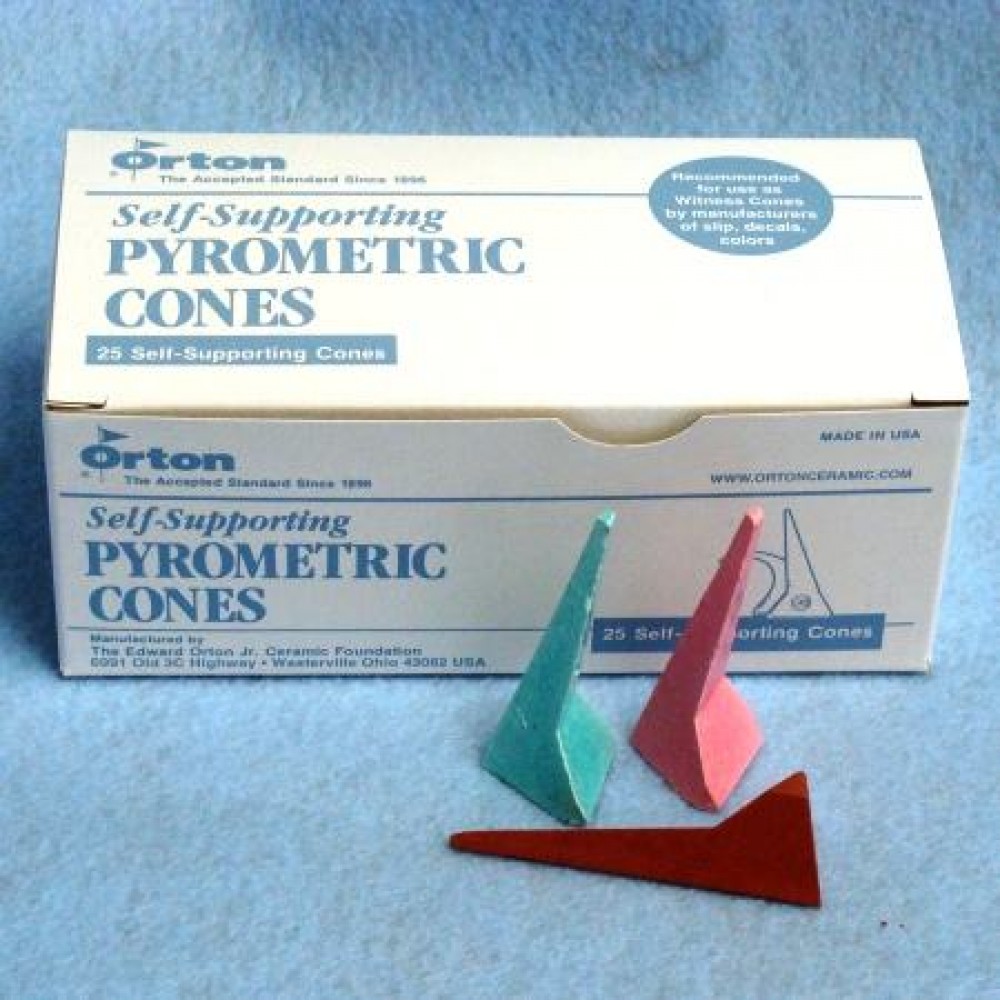

Self Supporting Cones 04 Pack of 20

$13.95

- Brand: Orton Cones

- Product Code: Orton SS 04

- Availability: In Stock

Description

04 Self Supporting Witness Cones - Pack of 25

Self-Supporting Cones are the most accurate and easiest to use pyrometric cones available.

They feature a built-in base for support during firing and require no cone holder or plaque. Correct height (1 ¾”) and angle (8°) are built in to help insure reproducible firings time after time.

Self-Supporting Cones are popular as witness cones on the kiln shelf to visually record and evaluate the heat work (the effect of temperature and time at temperature) in different locations throughout the kiln.

Pyrometric cones are recommended by glaze and kiln manufacturers to assure the proper amount of heat work was achieved during firing. Achieving the proper amount of heatwork allows the optimum ceramic properties and colors to be developed during the firing process. Pyrometric Cones will also help identify any subtle changes taking place inside the kiln before they impact your ware (changes over time due to thermocouple drift, degrading heating elements, etc.).

Thermocouples only measure temperature at one point inside the kiln. Pyrometric cones can be placed throughout the ware setting so you can easily monitor the heatwork your kiln produces where your product is being fired.

3 cone method for monitoring heat-work

Pyrometric cones are slender pyramids made from about 100 carefully controlled compositions. Each cone number is unique in measuring temperature within a small temperature range (less than 30°C). Cones measure the amount of heat absorbed. As the cone nears its maturing range, it softens and the tip begins to bend, drawn down by the influence of gravity.

Pyrometric cones are useful in determining when a firing is complete, if the kiln provided enough heat, if there was a temperature difference in the kiln or if a problem occurred during firing.

Cones are made from carefully controlled compositions and they bend in a repeatable manner (over a relatively small temperature range- less than 40ºF).

Small (junior) cones are used in a Kiln-Sitter™.

| Cone/Temperature Conversion Chart | ||||

| Cone | Temp at 108ºF/hr | Temp at 270ºF/hr | Kiln Color | Ware and Glaze Types |

| 10 | 2345 | 2381 | White | Stoneware Glaze |

| 9 | 2300 | 2336 | ||

| 8 | 2280 | 2320 | ||

| 7 | 2262 | 2295 | ||

| 6 | 2232 | 2269 | Porcelain Bisque | |

| 5 | 2167 | 2205 | ||

| 4 | 2124 | 2161 | Porcelain Glaze | |

| 3 | 2106 | 2138 | ||

| 2 | 2088 | 2127 | ||

| 1 | 2079 | 2109 | ||

| 01 | 2046 | 2080 | Yellow | |

| 02 | 2016 | 2052 | ||

| 03 | 1987 | 2019 | ||

| 04 | 1945 | 1971 | ||

| 05 | 1888 | 1911 | ||

| 06 | 1828 | 1855 | Bisque,Low Glaze | |

| 07 | 1789 | 1809 | Orange | Red Family Glazes |

| 08 | 1728 | 1753 | ||

| 09 | 1688 | 1706 | ||

| 010 | 1657 | 1679 | ||

| 011 | 1607 | 1641 | ||

| 012 | 1582 | 1620 | ||

| 013 | 1539 | 1582 | Red | |

| 014 | 1485 | 1540 | ||

| 015 | 1456 | 1504 | ||

| 016 | 1422 | 1465 | ||

| 017 | 1360 | 1405 | Glass Sagging | |

| 018 | 1319 | 1353 | China Paints | |

| 019 | 1252 | 1283 | Metallics, Lusters | |

| 020 | 1159 | 1180 | Dull Red | Decals |

| 021 | 1112 | 1143 | Glass Paint | |

| 022 | 1087 | 1094 | | |